VIBRATING FEEDERS

General Kinematics Vibrating Feeders offer an unequaled record of dependability and performance in the controlled feeding of bulk materials. GK Feeders are ideally suited for a wide range of bulk material handling applications in mining, power generation, and process industries. Installed units are handling ores, coal, aggregate, sand, powders, grain, and difficult to handle materials such as lignite coal.

PARA-MOUNT II? VIBRATORY CRUSHER FEEDER

Increased throughput and load responsive design are just two of the many advantages you will find when switching to General Kinematics PARA-MOUNT II? Vibratory Crusher Feeders.

Utilizing GK’s proven two-mass drive technology, the PARA-MOUNT II? requires up to 2/3rds less energy than traditional feeders of the same size, all while moving and metering MORE material.

GK feeders are available in standard and custom sizes to best fit your application.

Load responsive design.

2/3rds less energy than traditional feeders of the same size.

Available with cone or standard discharge

Standard sizing available

PARA-MOUNT II? VIBRATORY FEEDERS

Proven performance and maintenance-free operation make PARA-MOUNT II? Vibrating Feeders the first choice in vibratory feeders for the most demanding applications. PARA-MOUNT II? Vibrating Feeders can be designed using either a fixed or variable force drive, and utilize GK’s proven Two-Mass vibratory drive. This drive increases feed capacity, uses up to 2/3rds less energy, and provides exceptional reliability and ease of maintainability.

FEATURES:Two-Mass vibratory drive uses up to 2/3rds less energy than direct drive/brute force feeders.

Simple, extra-heavy-duty construction for years of trouble-free service.

Two-Mass drive system is self-compensating to automatically maintain constant feed rate for varying load and material changes.

Engineered to be low maintenance for continuous uptime.

Full enclosed motors (explosion proof available) and other drive components are fully accessible for easy service.

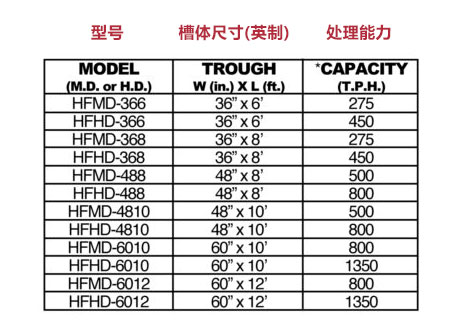

“QUICK-SHIP” PRE-ENGINEERED VIBRATING FEEDERS

General Kinematics PARA-MOUNT II? Pre-Engineered Vibrating Feeders are engineered with simple, heavy duty construction for years of trouble free service. Based on General Kinematics PARA-MOUNT II? Vibrating Feeders, this new version is now available in pre-engineered, quick ship sizes.

FEATURES:Moderate Density (M.D.) material up to 70 pcf max. includes 304 S.S. pan.

High Density (H.D.) material up to 120 pcf max. includes AR400 pan.

*Capacity based on unit declined 10 degrees with dry/good flowing material.

DIRECT-DRIVE VIBRATORY FEEDERS

General Kinematics Direct-Drive vibratory pan feeders are designed for rugged continuous duty operation. Utilizing compact and energy efficient vibratory motors, GK Direct-Drive feeders feed and meter the most difficult materials. Heavy-duty designs withstand the toughest environments, with GK installations still in operation for over 40 years.

FEATURES:Standard and custom engineered sizes available.

Drives can be mounted overhead or underneath the pan for ultimate process flexibility.

Liners can either be welded or bolted in, depending on your preference.

Available in optional specialty finishes and construction materials.

PARA-MOUNT? VIBRATORY FEEDERS

General Kinematics original PARA-MOUNT? Vibratory Feeders are designed to control the flow of bulk materials through the use of GK’s proven two-mass drive system. This system allows the feeder to automatically compensate for material head load and weight effect. This anti-dampening performance results in accurate volumetric feed rate control regardless of material headload variations.

PARA-MOUNT feeders utilize rubber springs and are designed to excel in difficult environments, including those with explosion-proof requirements. Each feeder is custom engineered for your specific application and process requirements.

Available with fixed and variable rate control packages.

Two-mass drive system compensates for material load.

Uses up to 2/3rds less horsepower compared to similar sized direct drive feeders.

Can be constructed from mild steel, abrasion resistant steel, stainless, or other exotic materials.