CLEANING ROOM SOLUTIONS

FULLY INTEGRATED CLEANING ROOM SOLUTIONS.

General Kinematics specializes in automation of cleaning room operations. From simple sorting conveyors to fully automated blast handling systems, GK can design a solution to maximize efficiency of the casting cleaning department in your foundry.

PRE-BLAST

General Kinematics blast weighing, metering, and loading solutions create the perfect charge for your blast system. Automated systems can be designed to change elevation, move from one cabinet to the other automatically, and convey in multiple directions for the ultimate in system design flexibility.

BLAST UNLOADING

GK blast unloading solutions reduce casting damage and noise. Conveyors are designed with a variety of materials that dampen sound. Flat stroke drives reduce material bouncing and the associated noise. GK Two-Way feeders allow for bi-directional conveyance of your product stream for multiple sorting lines or reject modes.

CASTING SORTING

Patented flat-stroke vibratory conveyor technology from General Kinematics optimizes efficiency while reducing worker fatigue. Flat stroke sorting conveyors can be designed to meet your sorting objectives utilizing multiple lane troughs, discharge chutes, side mounted scrap channels, and much more.

BLAST UNLOAD CONVEYORS

General Kinematics vibrating Blast Unload Conveyors quietly and efficiently transfer castings post-blast. Utilizing GK’s proven vibratory conveyor drive technology, vibrating Blast Unload Conveyors receive your cleaned castings from the blast machine and convey them away from the blast area for further processing. Conveyors are available with noise suppressing or rubberized decks to reduce noise and casting damage.

GK’s patented TWO-WAY? Feeder drive upgrade allows for completely horizontal conveying. This further reduces noise and is ideal for fragile castings. The TWO-WAY? can also be automatically controlled to change direction of flow if there is a problem somewhere down the line.

Available with GK’s standard conveyor drive or with our patented TWO-WAY? flat stroke drive.

Noise suppressing decks keep surrounding areas quiet.

Rubber deck linings can be included to prevent casting damage.

Bi-directional designs can change material flow depending on your process.

TWO-WAY? VIBRATORY FEEDERS

TWO-WAY? feeders from General Kinematics open up a wide range of process possibilities. The TWO-WAY? bi-directional conveyance allows you to alternate material flow for multi-directional product processing, for rejection of bad product, or any other process which may require multi-directional conveyance from a single unit. The units completely horizontal stroke shuffles material with no impact and a significant reduction in noise. Available in straight and all new bi-directional curved designs.

FEATURES:Uses a single low horsepower drive, reducing energy consumption.

Available in curves up to 90 degrees.

Horizontal stroke does not damage fragile product.

SHOT COLLECTION AND RECLAMATION SOLUTIONS

Collection

GK vibrating solutions for shot collection integrate into existing and new shot blast installations to collect, screen, and redistribute shot back into the cleaning system. From shot return conveyors to vibrating screens for separating sprue and sand, GK can supply you with a solution to improve your shot blast system performance.

Reclamation

GK’s shot classifier / reclaimer uses vibratory motion in combination with air classification to effectively clean shot prior to returning it to the blast system. By classifying and separating only “good” shot from broken shot and sand, wheel maintenance and increasing uptime and blast performance.

Low-horsepower, high efficiency drive system reduces maintenance and energy costs.

Low profile design fits into even the most difficult locations.

Shot classifier can deliver up to 98% clean shot back into your system to reduce wheel maintenance and wear, increasing casting cleaning performance.

BLAST LOAD FEEDERS

General Kinematics vibrating Blast Load Feeders offer unparalleled flexibility in system design and efficiency. Vibrating Blast Load Feeders can be designed to index forward, backward, up, down and side to side, as well as convey material in multiple directions. Optional automated gates, weigh cells, and other options allow you to precisely monitor and feed multiple shot blast machines with a single vibratory unit. Rail mounted feeders can index to each shot blast machine and feed material, then return to an accumulating feeder for the next material batch.

FEATURES:Blast Feeders utilize General Kinematics proven PARA-MOUNT II? vibratory feeder design.

Available with customized control packages or can be integrated into existing control systems.

SORTING CONVEYORS

General Kinematics vibratory Sorting Conveyors for post-blast processing present castings for easy access and sorting. GK’s patented flat-stroke conveyor technology, combined with multiple lane, sound deadening troughs, reduce worker fatigue and increase casting throughput.

GK vibratory Sorting Conveyors can be integrated into existing blast systems or combined with our complete blast automation solutions for a turn-key casting sorting system package that is guaranteed to boost foundry output and performance.

Flat stroke designs and sound deadening troughs reduce worker fatigue.

Conveyor troughs can be designed with multiple lanes to distribute finished product and scrap to different locations.

Custom systems can be designed around existing facility for simple process integration.

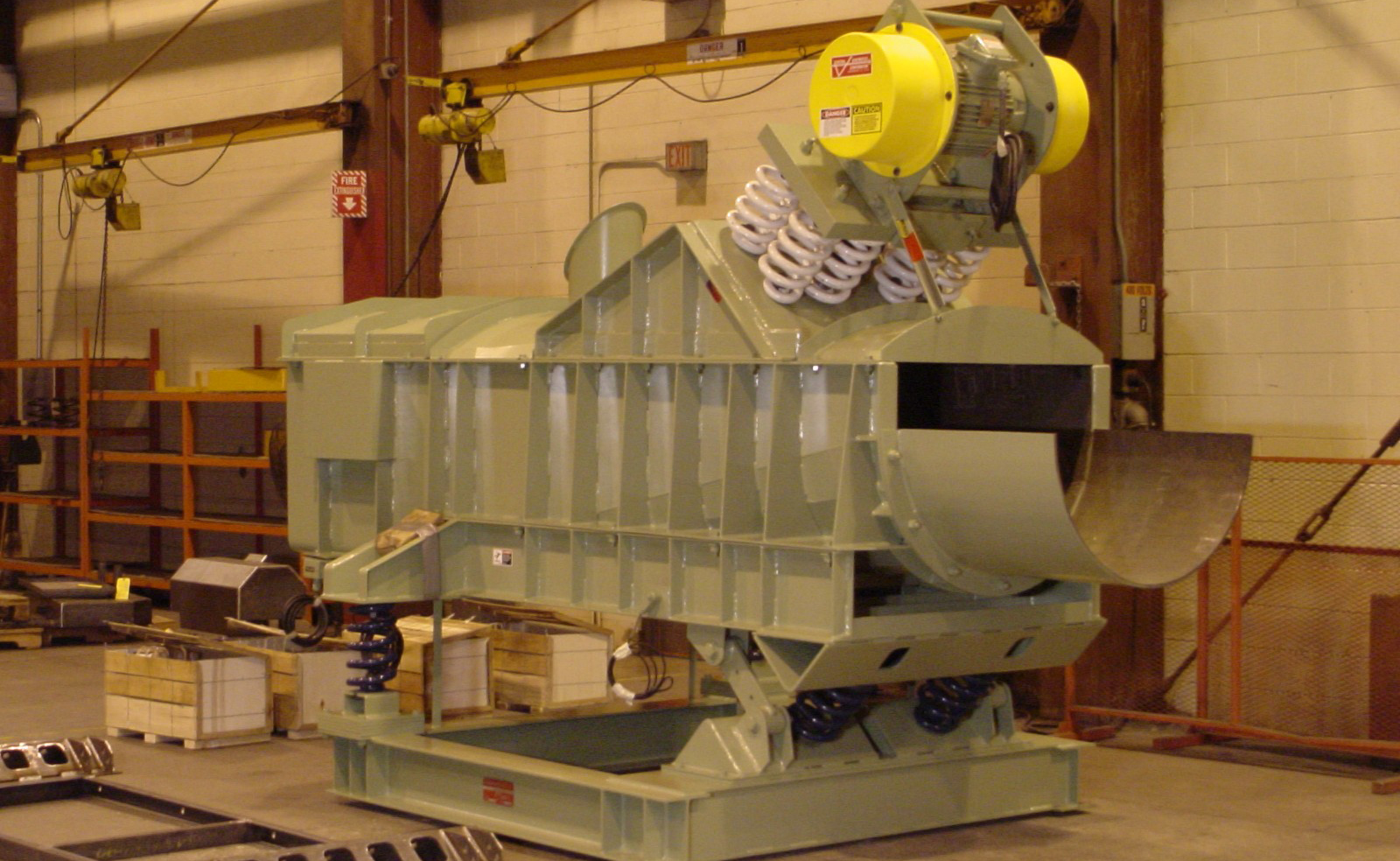

PARA-MOUNT II? VIBRATING FEEDERS

Proven performance and maintenance-free operation make PARA-MOUNT II? Vibrating Feeders the first choice in vibrating feeders for the most demanding applications. PARA-MOUNT II? Vibrating Feeders in either fixed or Variable Force configurations utilize a sub-resonant two-mass system. Mass A (the exciter) energizes mass B (the deck assembly) through precision engineered coil springs. Only small amounts of energy are needed to maintain the natural energy stored and released by the spring system. What this means for you is increased feed capacity, lower energy costs, and exceptional reliability and ease of maintainability. PARA-MOUNT II? Vibratory Feeders do more work with less energy, thanks to our two-mass, natural frequency design. Whether you are charging a feeder or metering sand or castings, each feeder is designed specifically to work to enhance your process.

FEATURES:

Two-mass vibratory drive can be designed with low horsepower foot mounted or double c flange motors.

Simple, extra-heavy duty construction for years of trouble-free service.

Two-mass, sub-resonant natural frequency design is self-compensating to automatically maintain constant feed rate for varying load and material changes.

Significant annual energy savings over brute or direct force designs.

Engineered to be low maintenance for continuous uptime.

Extra-Heavy duty design withstands heavy parts and abrasive materials.

METERING FEEDERS

GK Metering Feeders collect, weigh, and evenly distribute castings to blast machines. By combining vibratory feeders with weigh cells, gates, and modern control systems, GK Metering Feeders can accurately dispense the right amount of castings to your blast machines for optimal cleaning.

General Kinematics Metering Feeders are just a part of GK’s complete blast handling and cleaning systems. For more information about complete blast solutions, contact a GK Foundry Specialist.

Vibrating feeders use GK’s proven two-mass technology for significant energy savings over brute force designs.

Multiple feeders can be arranged for product accumulation and storage.

Metering feeders are an integral part of GK’s complete blast handling systems.